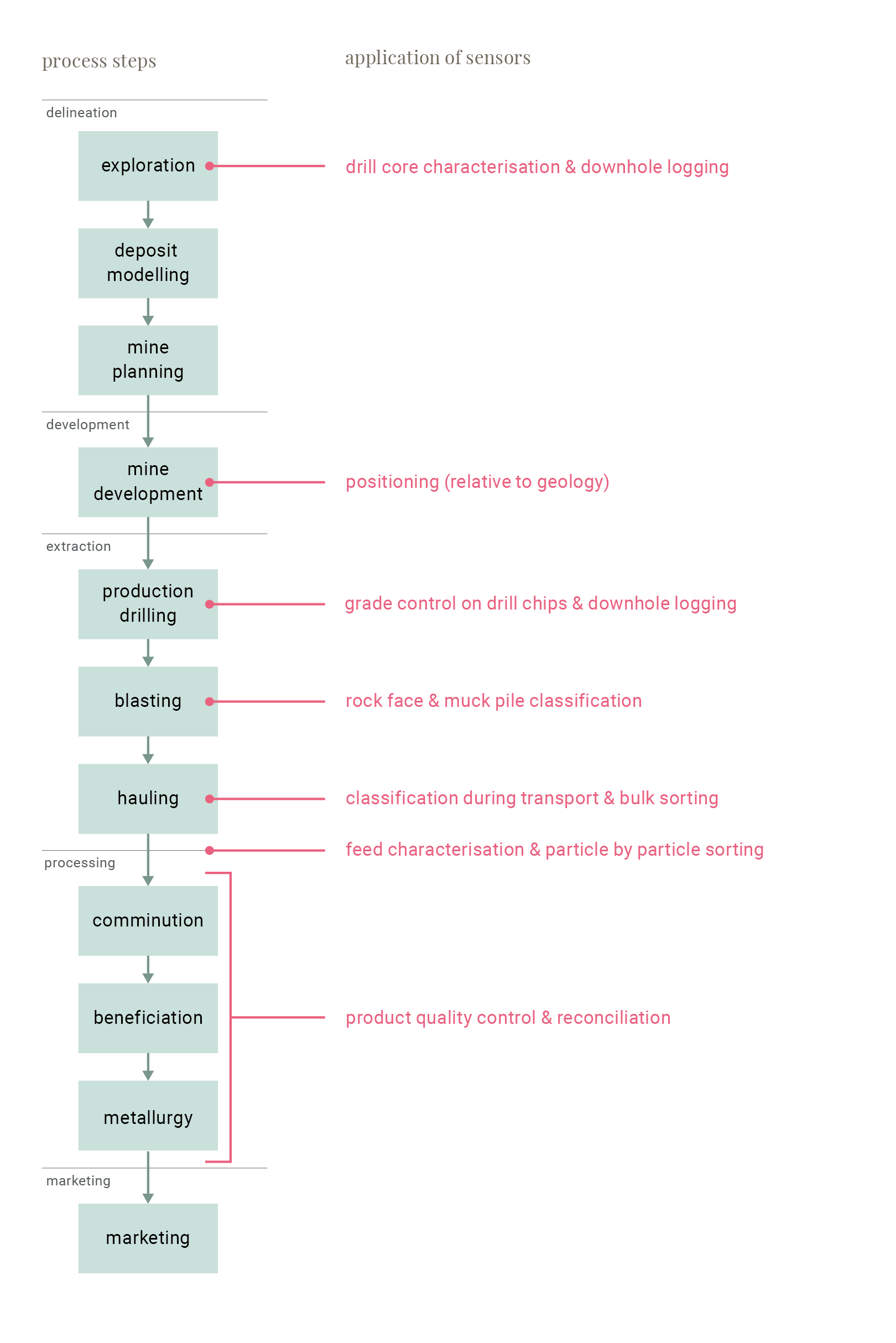

Sensors can be used to measure material properties during any process where the materials are exposed or can be accessed with an analyser or scanner. Within mining and mineral processing such access is possible at various process steps. The figure below shows an overview of the different processes within the mining value chain and the possible application areas for sensors. The value chain is generally sub-divided into:

- Deposit exploration & delineation

- Development of mine workings

- Extraction of resources

- Processing of the mined material

- Selling the product on the market

Sensor applications along the mining value chain.

source: PhD thesis M.Dalm (2018 – TU Delft), https://doi.org/10.4233/uuid:70a1e180-ef0c-4226-9af3-7e9dc3938c7f

Mining procedures differ depending on the commodity, deposit type, and the used mining method. The process steps presented in the figure above are typical for traditional mining methods in hard rock conditions, which accounts for a large part of the global mining activities. However, the process steps are different if rocks are softer and continuous mining machines can be used. In this case, drilling and blasting is not needed and the associated sensor opportunities are not available. These can often be replaced by other sensor opportunities, such as the integration of sensors on mining equipment.

For more information on the different mining methods and the mining value chain, the [related books] section of the RockDataAcademy provides several references to mine engineering books.

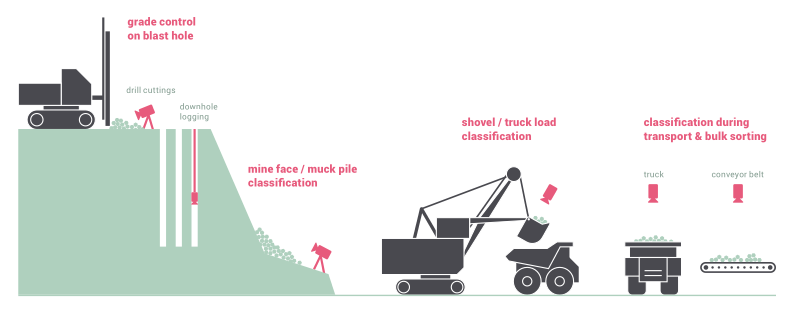

Opportunities during resource extraction

There are relatively many sensor opportunities during the actual mining of a deposit. Sensor-based analysis can be done in the field or during transport of the ore materials. When using drilling and blasting methods, it is additionally possible to use sensors for measurements down the drill holes or for scanning the produced drill chips. The figure below presents an overview of the sensor opportunities in open pit mining. Similar opportunities exist for underground mining operations.

Sensor opportunities during open-pit mining.

source: PhD thesis M.Dalm (2018 – TU Delft), https://doi.org/10.4233/uuid:70a1e180-ef0c-4226-9af3-7e9dc3938c7f

The information that is obtained from sensor-based analysis during material transport can also be used for sorting the ore materials. This concept is commonly referred to as sensor-based sorting.

Two different types of sensor-based sorting can be distinguished. First of all, it is possible to use the information from sensors that scan a shovel or truck load to route the trucks to different stock piles or processing streams. In a similar fashion, batches of material that are being transported on a conveyor belt can be sorted by using a conveyor belt scanner and a diverter gate. This type of sensor-based sorting is often referred to as bulk ore sorting.

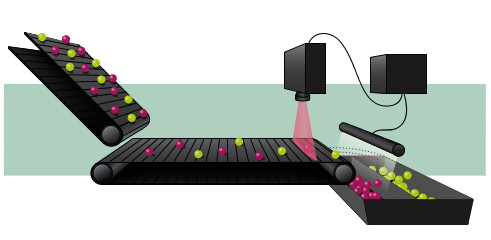

Another application of sensor-based sorting is to sort individual rock particles. Sorting equipment is available that can mechanically separate singular rock particles after detecting their properties with a sensor. The separation is often achieved with jets of compressed air that divert particles into a different stream. This type of sensor-based sorting is also referred to as particle sorting.

Concept of sensor-based particle sorting.

source: PhD thesis M.Dalm (2018 – TU Delft), https://doi.org/10.4233/uuid:70a1e180-ef0c-4226-9af3-7e9dc3938c7f

Example of a sensor-based particle sorting machine.

source: “Sensor-Based Sorting: The Future of Mining” by Rebecca G (2020 – SRC), https://www.src.sk.ca/blog/sensor-based-sorting-future-mining