The concentration of valuable minerals that determines ore grade is usually not constant or homogeneously distributed throughout a volume of rock that is an ore deposit. These minerals follow certain geological structures that were formed over millions of years. Some understanding of the mechanisms that created these structures is useful in the development and evaluation of sensor applications. This is because the possibilities and limitations of every sensor are determined by the properties of the materials that need to be measured. This means that differences in a rock’s hardness, colour, or density for example can influence the detection of ore grade.

Compositional heterogeneity

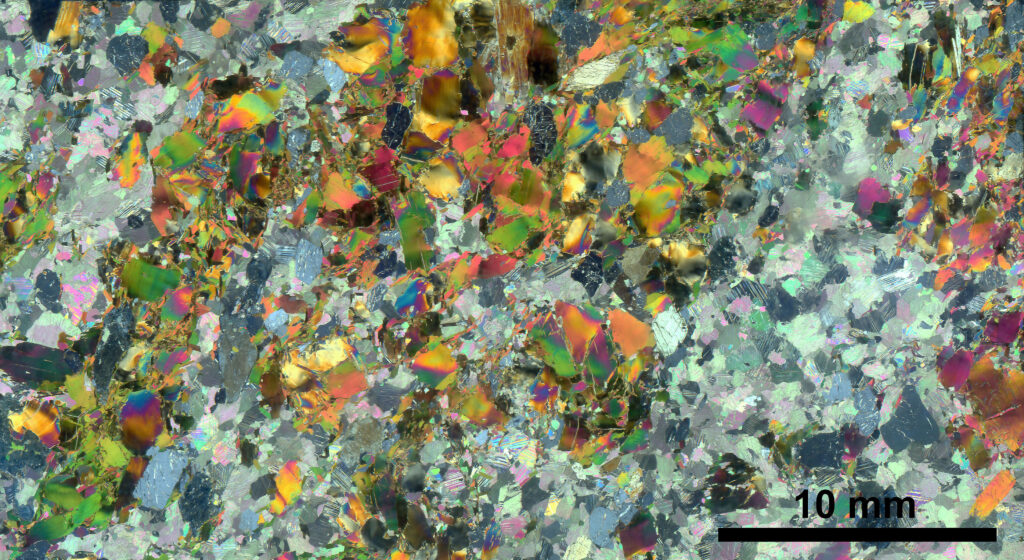

One of the most important properties of ores and rocks for the development of sensor applications is their compositional heterogeneity. By definition, a rock is composed of different minerals and therefore always heterogeneous. However, the way in which heterogeneity is perceived depends on the scale at which a rock mass is evaluated. At very small scales (µm – mm) the degree of heterogeneity is usually high as composition changes completely from one mineral to the other. The heterogeneity depends on the grain or crystal size of the individual minerals within the rock. The ore grade is very high when the mineral is of economic value, or zero when it is not.

Medium-scale heterogeneity

When comparing between rock masses at medium scales (cm – m), certain volumes can be considered homogenous when the relative amounts of the individual minerals within the rock is more or less constant. Heterogeneity at this scale usually results from the occurrence of different rock types and geological features such as faults, fractures, and veins. These are also often the features that drove the formation of valuable minerals for which a deposit is mined. Ore grades can therefore vary significantly depending on the vicinity to such features.

For a mine’s production planning, rock masses usually need to be evaluated at relatively large scales (1 – 100’s m). This is due to the equipment size that is required to make mining profitable. Apart from large-scale geologic features, rock masses are often considered to be homogeneous at this scale. The grade depends on the number and size of the mineralized geological features that occur within the mass. The occurrence of these features over relatively large scales is usually summarized in terms of a grade continuity. This grade continuity is used to model and estimate how ore grades change between different parts within a mine1.

Medium-scale heterogeneity

Large-scale heterogeneity

Economic cut-off grade

A certain economic cut-off grade is usually defined to determine which portions of a deposit are ore, and which are waste. The cut-off grade is often expressed in terms of the concentration of one or more minerals or elements that hold value. It is the minimum grade that is required in order for a mineral or metal to be economically mined. It is commonly determined by balancing the costs associated with mining and mineral processing to the profits that are obtained from selling the extracted minerals1,2.

In some cases, also the concentration of other components affect cut-off grade. Examples are minerals that decrease the efficiency of metal extraction, or that are harmful to the environment.

Since cut-off grade is usually based on economics, the boundaries of a deposit do not always correspond to the geologic boundaries in the area. An example of this are stockwork mineralizations, which are common in many deposit types. A stockwork is a complex system of small veins that can spread out over relatively large areas. Ore grade depends on the number of veins that occur within a certain block, which can change erratically in different directions. This means that boundaries between ore and waste can be irregular and vague.

Waste dilution

Waste dilution refers to the amount of waste rock in a mined batch of ore. This often occurs when mining is taking place close to the boundaries of ore and waste domains. Depending on the geology of the deposit, these boundaries may not be clear and sharp transitions. Due to inaccuracies in ore grade estimations it is therefore possible that mined ore is diluted with waste rock.

Waste dilution also results from the relatively large scale at which mining generally takes place. Even when ore-waste boundaries are relatively clear and sharp transitions, mining equipment is not always able to accurately follow these boundaries. A certain amount of dilution is usually also acceptable for mineral extraction processes, as long as the average grade of a batch is still above cut-off grade.

References

- Sinclair, A. J. & Blackwell, G. H. Applied Mineral Inventory Estimation. (Cambridge University Press, 2006).

- Hartman, H. L. & Mutmansky, J. M. Introductory Mining Engineering. (John Wiley & Sons, 2002).